- December 28, 2022

- Blog, Maintenance

- Posted by Brian Hall

- Comments Off on Winter is Here – Operating Your Wintex in Cold Weather

Cold weather brings its challenges to operating equipment. It is important to begin considering the effects of cold temperatures on the fluid system. Follow these extra tips for operating your Wintex during the winter months

- Do a daily walk around and also clear the equipment of any snow/ice buildup on components like the probe, probe scrapper, and platform. Check for any maintenance issues like a cracked hose, hydraulic leaks, or the condition of chains and the O ring.

- Viscosity & Fluid checks: Viscosity should be the first consideration when preparing fluid power systems for the Check the oil in both the engine and hydraulics so that it drips from the dipstick. If any fluid is too thick to drip off the end of a dipstick, it is too viscous to function properly, especially in the cold. Even though the freezing point that causes high-viscosity hydraulic oil to gel and becomes unusable is -10 degrees [...]

- December 28, 2022

- Blog, Maintenance

- Posted by Felix.Weber

- Comments Off on Winterize your Wintex

If you are done soil sampling until next spring, it is a good habit to fully service your Wintex and Honda motor, while sampling season is still fresh in your mind.

Keep it Clean: The first step should be to thoroughly clean the Wintex and take care of routine maintenance items. If using a pressure washer, just be careful around any electrical components.

Fully service the Honda Engine. The Honda owner’s manual has a detailed section on maintenance and off-season storage. What we like to do is change the oil, change the fuel filter, fill the gas tank, and use a fuel stabilizer. An oil change is especially important when it comes to winterizing small engines, as old oil can contain small contaminates that can be corrosive to the system if left sitting for a long period.

Service Your Wintex: Refer to our service videos and bulletins for more information on Wintex Service Videos.

We [...]

- December 28, 2022

- Blog, Maintenance

- Posted by Felix.Weber

- Comments Off on Service Update: Wintex 1000s, 2000, & 3000 Models

On occasion a client has called about a sticking probe, or a probe stuck in the ground. There are several possible causes of this including soil conditions. Below are steps to manually raise the probe up, along with some potential causes.

For any sensor issue, clean off sensor first. There might be some metal suck to the sensor (magnetic) giving false readings.

Stuck probe:

- Mounting height: The proper footplate height is 8 to 9 inches off the ground when the footplate is fully retracted. When the footplate does not rest on the soil, the Wintex can shift the changing angle of the probe when going down or up, which can cause the probe to become stuck, or causing excessive wear. It is important your vehicle not shift while sampling, which can cause the probe to become stuck

On trucks using our truck box frame: Adjust the mounting height of the Wintex on the [...]

- November 8, 2022

- Blog, Maintenance

- Posted by Felix.Weber

- Comments Off on Manually Using the Hydraulics to Pull the Probe Up

Manually Using the Hydraulics to Pull the Probe Up

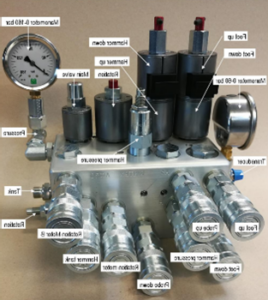

The hydraulics can be operated manually using the controls on the hydraulic block.

- Activate the probe rotation by pressing down the red rotation valve button to release the lock pin (will come up a bit). Turn the button counter-clockwise to activate probe rotation.

- Locate the hammer/probe valve. The probe goes down when pulling the valve. The probe goes up when pushing the valve. At the same time always activate the main valve by pressing it down when activating the other functions.

- Never lift the foot off the soil surface while the probe is in the ground. This can change the angle of the probe.

Remember to re-set the rotation valve before continuing to sample of the probe.